#precision farming components

Explore tagged Tumblr posts

Text

Enhance Performance with Precision-Engineered Crown Pinion 14Tx22T Suitable for Kirloskar

Agriculture is the backbone of any thriving economy, and for farmers, reliable machinery is critical for maximizing productivity. One such essential component is the Crown Pinion 14Tx22T, a small yet powerful gear system that ensures smooth operations in agricultural machinery, particularly in Kirloskar machines. At SBJ Nirmal Products, we specialize in precision-engineered crown pinions that empower farmers with unmatched durability and performance.

Let’s explore how SBJ Nirmal Products delivers excellence through its precision-engineered Crown Pinion 14Tx22T for Kirloskar machinery.

Introduction to Crown Pinion 14Tx22T

What is a Crown Pinion?

A crown pinion is a critical gear component used in various machinery systems. It is responsible for transmitting rotational motion and ensuring the smooth operation of machinery, particularly in farming equipment.

Role of Crown Pinions in Farming Machinery

In agricultural machinery like rotavators, the crown pinion plays a pivotal role in power transmission. It connects vital components, ensuring that machines operate efficiently and can handle heavy workloads in the field.

Why Choose Precision-Engineered Crown Pinion?

Importance of Precision Engineering

Precision engineering ensures that each component meets exact specifications. For a crown pinion, precision determines how smoothly the gears fit and perform under stress.

Benefits of Using High-Quality Crown Pinions

Improved power transmission efficiency

Reduced friction and wear

Increased lifespan of machinery

Minimized downtime and maintenance costs

SBJ Nirmal Products: A Trusted Name

History and Legacy of SBJ Nirmal Products

With decades of experience, SBJ Nirmal Products has become a name synonymous with quality and reliability in the agricultural machinery parts industry. Based in Ludhiana, Punjab, SBJ serves farmers across India and neighboring countries.

Commitment to Quality and Innovation

SBJ Nirmal Products focuses on precision engineering, using advanced technology and high-grade materials to deliver components that exceed customer expectations.

Key Features of SBJ Crown Pinion 14Tx22T

Material Strength and Durability

SBJ Crown Pinion 14Tx22T is manufactured using high-grade steel, ensuring superior strength and resistance to wear.

Design Accuracy for Perfect Fit

The precision-engineered design ensures compatibility with Kirloskar machinery, allowing for smooth and efficient operations.

Resistance to Wear and Tear

With advanced heat treatment processes, SBJ’s crown pinions are built to withstand tough agricultural conditions, offering long-lasting performance.

Benefits of Crown Pinion 14Tx22T for Kirloskar Machinery

Improved Machinery Efficiency

The perfect fit and durable design of SBJ Crown Pinion 14Tx22T enhance machinery efficiency, enabling farmers to get the most out of their equipment.

Reduced Downtime and Maintenance Costs

With a focus on durability, SBJ’s crown pinions reduce the need for frequent replacements, saving farmers valuable time and money.

Enhanced Productivity in Farming Operations

Reliable components ensure smooth machinery operations, allowing farmers to focus on maximizing their crop yield.

H2: How Crown Pinion 14Tx22T Enhances Performance

Precision Fit for Smooth Functionality

The precise design eliminates gaps and misalignment, ensuring seamless functionality.

Role in Power Transmission and Load Handling

The crown pinion effectively transmits power while handling heavy loads, a necessity in demanding farming operations.

Applications of Crown Pinion 14Tx22T

Use in Rotavators and Agricultural Machines

SBJ Crown Pinion 14Tx22T is widely used in rotavators, tillers, and other farming machinery for efficient soil preparation.

Compatibility with Kirloskar Machinery

Designed specifically for Kirloskar models, SBJ’s crown pinions ensure maximum performance and reliability.

Why SBJ Nirmal Products Stands Out

High-Grade Manufacturing Processes

SBJ employs advanced manufacturing techniques to produce precision-engineered parts.

Affordable Yet High-Performance Products

Farmers receive unmatched value with products that combine quality, durability, and affordability.

Understanding Kirloskar Machinery Needs

Importance of Reliable Spare Parts

Kirloskar machinery is widely recognized for its durability and performance. However, the true potential of these machines depends on using high-quality spare parts like the Crown Pinion 14Tx22T. Reliable components ensure smooth operations, minimize breakdowns, and extend the machine's life.

Ensuring Long-Term Machinery Performance

Precision-engineered parts like SBJ’s Crown Pinion help Kirloskar machinery deliver consistent performance, even under heavy agricultural workloads. Farmers can rely on SBJ components to handle challenging conditions without compromising productivity.

Customer Success Stories

Real-Life Testimonials from Farmers

Farmers across India have shared their positive experiences with SBJ Nirmal Products. Here are a few stories:

“After switching to SBJ’s Crown Pinion 14Tx22T, my Kirloskar machine runs smoother than ever. I’ve seen a significant reduction in maintenance costs.” – Farmer from Punjab

“SBJ’s parts are durable and fit perfectly. My machine works like new again!” – Farmer from Nepal

Case Study: Performance Boost with SBJ Crown Pinion

A farmer in Ludhiana faced frequent machinery downtime due to poor-quality spare parts. After installing SBJ Nirmal’s Crown Pinion 14Tx22T, he reported:

30% improvement in machinery efficiency

40% reduction in maintenance expenses

Increased productivity during the sowing season

Where to Buy SBJ Crown Pinion 14Tx22T

Authorized Dealers and Distributors

SBJ Nirmal Products has a vast network of authorized dealers across India and neighboring countries like Bangladesh, Nepal, and Sri Lanka.

Online Purchase Options

For convenience, SBJ’s products are also available on trusted e-commerce platforms, ensuring quick delivery and genuine quality.

SBJ Nirmal Products’ Global Reach

Exporting to India, Bangladesh, Nepal, and Sri Lanka

SBJ Nirmal Products has established a strong presence not just in India but also in neighboring countries. Farmers in these regions trust SBJ for their high-performance spare parts.

International Standards in Manufacturing

SBJ Nirmal adheres to global quality standards, ensuring every product meets the needs of farmers worldwide.

Conclusion: Investing in Quality with SBJ Nirmal Products

Choosing SBJ Nirmal Products for your Kirloskar machinery means investing in quality, durability, and performance. The Crown Pinion 14Tx22T is a testament to SBJ’s commitment to supporting farmers with precision-engineered components that enhance productivity and reduce costs.

For farmers seeking reliable, long-lasting spare parts, SBJ Nirmal Products remains the ultimate choice, empowering agriculture with innovative and high-performance solutions.

#Crown Pinion 14Tx22T#SBJ Nirmal Products#Kirloskar machinery parts#precision-engineered crown pinion#durable crown pinion#agricultural machinery parts#high-quality spare parts#rotavator spare parts#crown pinion for Kirloskar#SBJ Nirmal in Ludhiana#reliable farming components#crown pinion exporter#Kirloskar crown pinion supplier#spare parts for farming machines#agricultural productivity solutions#SBJ Nirmal global reach#farming efficiency with crown pinion#long-lasting machinery parts#precision farming components#trusted agricultural parts supplier.

0 notes

Text

This story originally appeared on Vox and is part of the Climate Desk collaboration.

Odorless and colorless, methane is a gas that is easy to miss—but it’s one of the most important contributors to global warming. It can trap up to 84 times as much heat as carbon dioxide in the atmosphere, though it breaks down much faster. Measured over 100 years, its warming effect is about 30 times that of an equivalent amount of carbon dioxide.

That means that over the course of decades, it takes smaller amounts of methane than carbon dioxide to heat up the planet to the same level. Nearly a third of the increase in global average temperatures since the Industrial Revolution is due to methane, and about two-thirds of those methane emissions comes from human activity like energy production and cattle farming. It’s one of the biggest and fastest ways that human beings are warming the Earth.

But the flip side of that math is that cutting methane emissions is one of the most effective ways to limit climate change.

In 2021, more than 100 countries including the United States committed to reducing their methane pollution by at least 30 percent below 2020 levels by 2030. But some of the largest methane emitters like Russia and China still haven’t signed on, and according to a new report from the International Energy Agency, global methane emissions from energy production are still rising.

Yet the tracking of exactly how much methane is reaching the atmosphere isn’t as precise as it is for carbon dioxide. “Little or no measurement-based data is used to report methane emissions in most parts of the world,” according to the IEA. “This is a major issue because measured emissions tend to be higher than reported emissions.” It’s also hard to trace methane to specific sources—whether from natural sources like swamps, or from human activities like fossil fuel extraction, farming, or deforestation.

Researchers are gaining a better understanding of where methane is coming from, surveilling potential sources from the ground, from the sky, and from space. It turns out a lot of methane is coming from underappreciated sources, including coal mines and small oil and gas production facilities.

The report also notes that while there are plenty of low-cost tools available to halt much of this methane from reaching the atmosphere, they’re largely going unused.

The United States, the world’s third largest methane-emitting country, has seen its methane emissions slowly decline over the past 30 years. However, the Trump administration is pushing for more fossil fuel development while rolling back some of the best bang-for-buck programs for mitigating climate change, which will likely lead to even more methane reaching the atmosphere if left unchecked.

Where Is All This Methane Coming From?

Methane is the dominant component of natural gas, which provides more than a third of US energy. It’s also found in oil formations. During the drilling process, it can escape wells and pipelines, but it can also leak as it’s transported and at the power plants and furnaces where it’s consumed.

The oil and gas industry says that methane is a salable product, so they have a built-in incentive to track it, capture it, and limit its leaks. But oil developers often flare methane, meaning burn it off, because it’s not cost-effective to contain it. That burned methane forms carbon dioxide, so the overall climate impact is lower than just letting the methane go free.

And because methane is invisible and odorless, it can be difficult and expensive to monitor it and prevent it from getting out. As a result, researchers and environmental activists say the industry is likely releasing far more than official government estimates show.

Methane also seeps out from coal mines—more methane, actually, than is released during the production of natural gas, which after all is mostly methane. Ember, a clean-energy think tank, put together this great visual interactive showing how this happens.

The short version is that methane is embedded in coal deposits, and as miners dig to expose coal seams, the gas escapes, and continues to do so long after a coal mine reaches the end of its operating life. Since coal miners are focused on extracting coal, they don’t often keep track of how much methane they’re letting out, nor do regulators pay much attention.

According to Ember, methane emissions from coal mines could be 60 percent higher than official tallies. Abandoned coal mines are especially noxious, emitting more than abandoned oil and gas wells. Added up, methane emitted from coal mines around the world each year has the same warming effect on the climate as the total annual carbon dioxide emissions of India.

Alarmed by the gaps in the data, some nonprofits have taken it upon themselves to try to get a better picture of methane emissions at a global scale using ground-based sensors, aerial monitors, and even satellites. In 2024, the Environmental Defense Fund launched MethaneSAT, which carries instruments that can measure methane output from small, discrete sources over a wide area.

Ritesh Gautam, the lead scientist for MethaneSAT, explained that the project revealed some major overlooked methane emitters. Since launching, MethaneSAT has found that in the US, the bulk of methane emissions doesn’t just come from a few big oil and gas drilling sites, but from many small wells that emit less than 100 kilograms per hour.

“Marginal wells only produce 6 to 7 percent of [oil and gas] in the US, but they disproportionately account for almost 50 percent of the US oil and gas production-related emissions,” Gautam said. “These facilities only produce less than 15 barrels of oil equivalent per day, but then there are more than half a million of these just scattered around the US.”

There Are Ways to Stop Methane Emissions, but We’re Not Using Them

The good news is that many of the tools for containing methane from the energy industry are already available. “Around 70 percent of methane emissions from the fossil fuel sector could be avoided with existing technologies, often at a low cost,” according to the IEA methane report.

For the oil and gas industry, that could mean something as simple as using better fittings in pipelines to limit leaks and installing methane capture systems. And since methane is a fuel, the sale of the saved methane can offset the cost of upgrading hardware. Letting it go into the atmosphere is a waste of money and a contributor to warming.

Capturing or destroying methane from coal mines isn’t so straightforward. Common techniques to separate methane from other gases require heating air, which is not exactly the safest thing to do around a coal mine—it can increase the risk of fire or explosion. But safer alternatives have been developed. “There are catalytic and other approaches available today that don’t require such high temperatures,” said Robert Jackson, a professor of earth system science at Stanford University, in an email.

However, these methods to limit methane from fossil fuels are vastly underused. Only about 5 percent of active oil and gas production facilities around the world deploy systems to zero out their methane pollution. In the US, there are also millions of oil and gas wells and tens of thousands of abandoned coal mines whose operators have long since vanished, leaving no one accountable for their continued methane emissions.

“If there isn’t a regulatory mandate to treat the methane, or put a price on it, many companies continue to do nothing,” Jackson said. And while recovering methane is ultimately profitable over time, the margins aren’t often big enough to make the up-front investment of better pipes, monitoring equipment, or scrubbers worthwhile for them. “They want to make 10 to 15 percent on their money (at least), not save a few percent,” he added.

And rather than getting stronger, regulations on methane are poised to get weaker. The Trump administration has approved more than $119 million to help communities reclaim abandoned coal mines. However, the White House has also halted funding for plugging abandoned oil and gas wells and is limiting environmental reviews for new fossil fuel projects. Congressional Republicans are also working to undo a fee on methane emissions that was part of the 2022 Inflation Reduction Act. With weaker incentives to track and limit methane, it’s likely emissions will continue to rise in the United States. That will push the world further off course from climate goals and contribute to a hotter planet.

11 notes

·

View notes

Text

I made the Pink Cake from The Official Stardew Valley Cookbook!

This cake was an experience to make. I’m not a stranger to baking cakes and making frosting from scratch, but this recipe threw me several curves that I didn’t expect. It had three parts: the cake, the frosting, and the jam filling. I followed the recipe exactly (even going as far as finding farm fresh duck eggs!) and I wanted to share my thoughts on the finished product.

The cake itself is super spongey and has a nice crumb to it. I think this is likely due to the duck eggs, but also to the reaction of the acidic buttermilk with the basic baking soda. It was also a little on the dry side, but that was probably my fault as I left it in the oven for a bit because I was sort of terrified of the unpasteurized eggs and wanted to be sure it was cooked all the way through!

I have always wondered what this cake would taste like because the in-game recipe calls for melon. The jam filling between the layers is where the melon factors in: watermelon, to be precise. I think if I made the jam again I would cut back on the lemon zest because the lemon largely overpowered the watermelon and strawberry flavors.

The iconic frosting gets its pink color from ground up dehydrated strawberries. I thought that this would give it a nice strawberry flavor, but I could barely taste the strawberry when I sampled the frosting on its own. The frosting is very creamy and has a lovely texture, though! If I make this frosting again, which I definitely plan to for some of my other favorite cake recipes, I might add a couple drops of strawberry extract to enhance the flavor a bit.

All in all, the different components of this cake come together quite nicely. It was not overly sweet, much to my surprise, but it was very fruity. The jam in the middle ended up being my favorite part, even despite the overpowering lemon. I also wasn’t wishing for more strawberry flavor in the frosting once it was on the cake because there was so much else going on in terms of complex flavors.

This recipe was good overall, and I can honestly say that I’ve never tasted anything quite like it. That said, I don’t think I would go to the trouble of following the recipe exactly again unless my kids ask me to someday down the line. Which, at that point, I might as well shape the cake into a duck and decorate its head with popcorn because there were moments when this recipe almost broke me.

A couple of notes for anyone who might be thinking of making a Pink Cake of their own:

-2 duck eggs = 3 chicken eggs

-buttermilk: you can buy it at the store pre-made, or just add 1 tablespoon of white vinegar per 1 cup of milk and let it sit for at least 10 minutes

-make sure your butter and cream cheese are at room temperature, not melted! Just put them out on the counter a few hours before you start baking

Update:

Despite what I said earlier, I actually did make this recipe again. I had to use up my last couple of duck eggs somehow! I made a few tweaks, though, and I wanted to share them here!

Jam: I didn’t even add half of the listed amount of lemon zest this time. I recommend this 100%, as now I can actually taste the watermelon and strawberry instead of just the lemon!

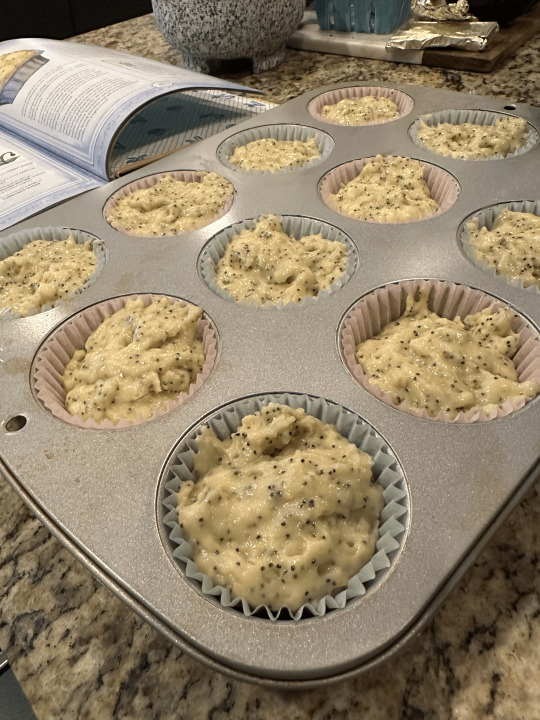

Cake: I made cupcakes instead of a full sized cake this time!

This recipe made 24 standard sized cupcakes. I baked them for 21 minutes (starting at 18 and then adding a minute before checking with a toothpick each time).

#stardew valley#stardew valley cookbook#Stardew valley recipe#pink cake#cake#baking#duck cake— I mean pink cake#The Official Stardew Valley Cookbook#Stardew recipes#sdv#sdv cookbook#sdv recipes

42 notes

·

View notes

Text

Poppyseed Muffin

(Playing some catch-up here, so just imagine it's mid-Feburary, not mid-March, for the sake of this post!)

Two recipes in, I realized one of the major challenges of cooking through the winter section of this cookbook: I don't live in Pelican Town. More specifically, I don't live in a place where the seasons--winter in particular--are aesthetically and climatologically consistent in the way things are on grandpa's farm. When it's 60 degrees outside, a winter recipe that'd be cozy at 30 might not hit the same.

That was precisely the case when I was preparing to dive into the cooking mines for round two. Fortunately, there are certain treats that transcend seasonal specificity, including the mighty poppyseed muffin.

I was excited to try one of the cookbook's baked goods. I'm a constant baker (thanks in part to an ongoing fascination with wild fermentation), making bread, cookies, and various pizza doughs on a regular basis. Muffins aren't a part of the typical rotation, though, and when I have made them, I haven't usually worried about muffin cups. But that's what ConcernedApe calls for, so that's what ConcernedApe gets! I couldn't find purple (the recommended color) at the grocery store, so I went for a pack that included pink and blue, like a nice lavender split into its two component parts.

Honestly, I've never made anything with poppy seeds either, so this was a nice chance to get to know the little buggers. They whisked nicely into the dry ingredients, breaking from little clumps into individual flecks, my whisking powered by tiny cups of tea (tucked just behind the mixing bowl above).

The title of the recipe doesn't name-drop lemon, but lemon zest and juice are key contributors here. I mixed those in with the rest of the wet ingredients, letting the batter sit as suggested for half an hour to puff up before dividing it among the cups and sprinkling with raw sugar.

After the division, it was into the oven for a quick bake. I appreciate the recipe's temperature precision, with an adjustment about halfway through the muffins' time in the oven.

Et voilà! A simpler journey than last post's eggplant parmesan, leading to some delicious muffins. In addition to the acidity of the lemon balancing the muffins' sweetness, the texture contrast of the raw sugar topping and poppy seeds with the fluffiness of the muffin was a delight. Other than advising you to order purple muffin cups ahead of time in case your local Joja Mart doesn't stock them, no notes! These muffins did indeed have a soothing effect, even on an unseasonably warm winter's day.

youtube

4 notes

·

View notes

Text

Why MSERW Pipes Are Ideal for Oil & Gas Pipelines

In the complex and high-stakes world of oil and gas transportation, the infrastructure must be built on a foundation of safety, durability, and cost-efficiency. Among the critical components of this infrastructure are the pipelines that transport crude oil, natural gas, and refined petroleum products over long distances and under harsh conditions. One of the most reliable materials used in such pipeline systems today is the MSERW pipe, short for Mild Steel Electric Resistance Welded pipe. Known for its strength and cost-effectiveness, MSERW pipes are increasingly becoming the preferred choice for oil and gas projects across India, particularly in industrial hubs like Gujarat.

In this blog, we explore why MSERW pipes are ideal for oil and gas pipelines, their technical advantages, and why choosing the right supplier—like a trusted MSERW Pipe Supplier in Gujarat is essential for long-term project success.

What Are MSERW Pipes?

MSERW (Mild Steel Electric Resistance Welded) pipes are made using a high-frequency electric resistance welding process. Mild steel plates or coils are rolled into cylindrical shapes and welded longitudinally without the use of any filler material. This method ensures consistent weld strength, smooth internal surfaces, and precise dimensional control.

Due to their favorable mechanical and chemical properties, MSERW pipes are suitable for a wide range of applications, particularly in the oil and gas industry where reliability is non-negotiable.

Key Benefits of MSERW Pipes for Oil & Gas Pipelines

1. High Strength and Durability:

Oil and gas pipelines often traverse difficult terrain and are exposed to high pressure, corrosive environments, and temperature fluctuations. MSERW pipes offer excellent tensile strength and toughness, making them ideal for handling such challenging conditions.

The electric resistance welding process enhances the pipe's structural integrity, ensuring long service life with minimal maintenance—an essential requirement in pipeline projects that demand continuous operation over decades.

2. Smooth Internal Surface:

One of the less-discussed yet important features of MSERW pipes is their smooth internal bore, which reduces friction during fluid transmission. This translates into improved flow efficiency and reduced pumping costs, which can add up significantly over time in oil and gas transportation networks.

3. Dimensional Accuracy:

Precision is crucial in pipeline design. MSERW pipes are known for their accurate diameters and consistent wall thickness, which allows for better joint fitting, easier welding, and reduced chances of leakage or pressure drops. This dimensional accuracy makes MSERW pipes a reliable choice in critical applications.

4. Corrosion Resistance:

Oil and gas pipelines often carry chemically reactive substances. MSERW pipes can be coated with anti-corrosive layers like epoxy or zinc, enhancing their resistance to harsh environmental and chemical exposure. A reliable MSERW Pipe Provider in Gujarat will often offer customization options like internal and external coatings to match specific project needs.

5. Cost-Effective Solution:

Compared to other pipe types such as seamless or spiral welded pipes, MSERW pipes are more economical while still delivering excellent performance. Their relatively lower manufacturing costs and ease of installation contribute to reduced overall project expenses—without compromising on quality or safety.

Applications of MSERW Pipes in the Oil & Gas Industry

Due to their versatility, MSERW pipes are used across several oil and gas infrastructure components, such as:

Oil transmission pipelines:

Natural gas distribution lines:

Petroleum refining pipelines:

Subsea risers and flowlines:

Tank farm pipelines:

Offshore platform connections:

Whether it's a massive cross-country crude oil pipeline or a localized gas distribution system in Gujarat, MSERW pipes meet the performance criteria required in each scenario.

Why Choose a Trusted MSERW Pipe Supplier in Gujarat?

When it comes to industrial products like pipelines, choosing the right supplier can make or break the success of your project. Gujarat, being a key industrial state, is home to many steel and pipe manufacturers. However, not all suppliers offer the same level of product quality, customization, or after-sales support.

A reliable MSERW Pipe Supplier in Gujarat will provide:

Test-certified products meeting IS, API, or ASTM standards

Custom sizes, thicknesses, and coatings

Timely delivery for project timelines

Technical support for design and installation

Competitive pricing for bulk orders

Whether your project is located in Jamnagar, Ahmedabad, Vadodara, or the coastal industrial belt, sourcing from a reputed MSERW Pipe Provider in Gujarat ensures you receive consistent quality and service.

Sustainability and Environmental Compliance:

Sustainability is increasingly becoming a core concern in infrastructure development. MSERW pipes are eco-friendly due to their efficient manufacturing process and recyclability. Modern MSERW manufacturing facilities in Gujarat follow environmental norms that align with international standards.

Additionally, the energy-efficient flow facilitated by the smooth internal surface of MSERW pipes reduces the carbon footprint associated with fuel transportation. By selecting a reputed MSERW Pipe Provider in Gujarat, you're also contributing to environmentally responsible construction practices.

Conclusion: A Pipe You Can Trust:

In conclusion, MSERW pipes offer a powerful combination of strength, durability, cost-effectiveness, and precision—making them a go-to solution for oil and gas pipelines. Their performance in both onshore and offshore environments has been proven across numerous large-scale projects.

If you’re looking for a reliable and quality-driven supplier for your next project, partnering with a reputed MSERW Pipe Supplier in Gujarat is the right move. Not only will you gain access to high-quality products, but you'll also benefit from industry expertise, logistical support, and tailored solutions that match your pipeline requirements.

Make the smart choice—invest in MSERW pipes and work with a professional MSERW Pipe Provider in Gujarat to ensure your oil and gas infrastructure is built to last.

6 notes

·

View notes

Note

Happy WBW! If the 7th station does synthetic meat and organs, as well as drugs and medicine, what do the other stations do?

Happy WBW!

I haven’t 100% delineated all the stations but I’ll give you what I have. Keep in mind all the stations are semi-sufficient - they couldn’t survive long-term on their own, but all of them have some level of food provision, medicine, mechanics, etc. For example you could absolutely get treatment for an injury or medication for a common illness on any station, but a surgery or a rare drug (like Nellie’s detox meds) are only available on Seventh Station.

First Station and Fifth Station I haven’t worked out precisely. I know First Station is the biggest station with the most people, but I haven’t quite worked out what those people do. Fifth Station’s worldbuilding is mostly focused on their theocracy so far so I’m not entirely sure what their station function centers around. I have the others though!

Second Station is responsible for agriculture. They grow food, natural textiles, and flowers as a luxury purchase. They don’t handle meat because they don’t raise animals on the stations, but they handle all sorts of growing plants. They also make honey! (I lied just in the slightest about animals. They have bees on the stations, but you’ll only ever see them in the farming areas).

Third Station handles entertainment. They make nice clothes, fancy food and most pre-prepared food, and entertainment pieces like movies, books, shows, puzzles, and toys.

Fourth Station is responsible for mechanics and component manufacturing. They make and repair shuttles and station components. Building and designing replacements for old parts and handling all the maintenance for the stations is their primary responsibility.

Sixth Station does manufacturing. They produce artificial textiles and do a lot of materials recycling. Broken components are shipped to Sixth Station to be broken down and repurposed for new components (as a side note, this is why Stellaris and Ambition are engaged - the Fourth and Sixth stations want to foster closer ties because their industries are heavily intertwined).

Thank you for the ask, I hope this was interesting! If you have any thoughts (or ideas on First and Fifth stations) I’d love to hear :)

9 notes

·

View notes

Text

Precision irrigation boosts fruit exports and citrus farming in Brazil's Northeast

In 2024, the Brazilian Northeast witnessed growth in irrigated fruit farming, notably in grape, melon, and mango cultivation. This development has become a key component of the region's agricultural output. Data from the Brazilian Association of Fruit and Derivative Producers and Exporters (Abrafrutas) indicated a 5.09% increase in Brazilian fruit exports in the first half of 2024, totaling US$511.9 million. The adoption of precision irrigation played a critical role in enhancing both productivity and quality.

Continue reading.

2 notes

·

View notes

Text

When I joined an international trading company in 2005, I began discovering the demands of final markets. Brazil, at that time, was already one of the largest urea consumers in the world. However, most of the imported urea was in prilled form. Those days are now gone. Today, if I’m not mistaken, around 95 percent of Brazil's urea imports consist of granular urea. The same can be said for the US, all of Europe, and many other countries.

So, why has granular urea become more widely used than prilled urea in the last 15–20 years? Primarily, this shift has occurred due to advancements in agricultural practices and the evolving needs of farmers. Granular urea offers several advantages that have driven this change, making it the preferred choice for modern farming.

Granular urea is physically larger and more uniform in size compared to prilled urea. This uniformity allows for better mechanical handling and more precise application using modern spreading equipment. The consistency in size reduces the risk of uneven application, which can lead to over-fertilisation in some areas and under-fertilisation in others. This precision is particularly important in large-scale farming operations, where efficiency and accuracy are crucial.

Granular urea tends to be more resistant to environmental factors, such as wind and moisture, compared to prilled urea. The larger, denser granules are less likely to be blown away by wind or to absorb moisture from the air, which can cause caking or dissolution before application. This stability helps ensure that the fertiliser remains effective until it reaches the soil, reducing waste and improving overall crop yield.

The physical properties of granular urea make it more compatible with other types of fertilisers in blended applications. Farmers often use blends of different nutrients tailored to specific crop needs, and the uniform size and density of granular urea allow for better mixing with other fertiliser components. This compatibility is key in precision agriculture, where specific nutrient delivery is critical for optimising crop production.

Granular urea generally has a slower release rate compared to prilled urea. This slower release helps reduce nitrogen volatilisation, where nitrogen is lost to the atmosphere as ammonia gas before it can be absorbed by the soil. This reduction in volatilisation means that more of the applied nitrogen is available for plant uptake, improving the efficiency of fertiliser use and reducing environmental impact.

As global agriculture has evolved, there has been a greater demand for fertilisers that support large-scale, intensive farming practices. Fertiliser manufacturers have responded by increasingly producing granular urea to meet this demand. Additionally, as more regions adopt mechanised farming techniques, the advantages of granular urea over prilled urea have become more apparent, further driving the shift in usage.

To summarise, as I have mentioned in my previous post, education and more sophisticated farming operations are key to these developments.

#urea #brazil #fertilisers #fertilizers #imstory #usa #europe #eu

2 notes

·

View notes

Text

About FixHom

The Best Home Mintenance & Repair Service

Welcome to FixHom, your premier destination for all your home renovation, maintenance, and repair needs in Peshawar, Pakistan. With a commitment to excellence and a focus on professionalism, we are dedicated to providing comprehensive services tailored to meet the unique requirements of our customers.

At FixHom, we understand the importance of maintaining a comfortable and functional living space. That’s why we offer a wide range of services, including but not limited to construction, renovation, reformation, maintenance like pluming or electircal work and repair for homes, farms, commercial premises, and more. Whether you’re dealing with a leaky faucet, a malfunctioning appliance, or planning a complete home renovation, our team of skilled professionals is here to assist you every step of the way.

FixHom Professional Plumbers & Electricians

At FixHom, we take great pride in our team of skilled professionals, including our Plumbers and Electricians, who are recognized as some of the finest in the industry. Each member of our team possesses extensive experience and undergoes rigorous training to hone their skills in their respective fields. With a deep understanding of plumbing systems, fixtures, and electrical components, our technicians bring a wealth of knowledge to every project they undertake. Whether it’s fixing a leaky faucet, repairing faulty wiring, or installing new fixtures, our technicians approach each task with precision and care, leaving no room for errors.

3 notes

·

View notes

Text

What is Hydroponic Farming System

It is the skill of growing plants in the absence of soil. Hydroponic system depends on a water based nutrient rich solution.

Hydroponic is a method of growing plants in a controlled environment (eg-greenhouses) where nutrients are dissolved in water and delivered directly to the plant’s roots instead of relying on soil for support and nutrition. The hydroponic system utilizes various substrates such as perlite, coconut coir or even air to anchor the plants. The nutrition solution, which contains all the essential elements necessary for plant growth, is carefully monitored and adjusted to ensure optimal conditions.

Here are some key components of Hydroponic Farming -

Growing medium : Instead of soil, hydroponic system use various growing mediums such as rock wool, perlite, coconut coir or even air (Vertical Farming) to support plant roots

Nutrients Solution: A carefully balanced mixture of essential nutrients is dissolved in water and delivered directly to the plant roots. This ensures that plants receive the precise nutrients they need for optimal growth.

Environmental Control: Hydroponic systems enable growers to fine-tune environmental factors like temperature, humidity, light and CO2 levels to create ideal conditions for plant growth . This level of control minimizes the risk of pests and diseases.

Water Recycling: Hydroponics is highly water efficient. Unlike traditional farming which can be water-intensive, hydroponic systems recirculate water, reducing overall consumption. This makes it particularly attractive with water scarcity.

Hydroponic Farming in India -

In India, hydroponic farming is gaining traction due to its potential to address various agricultural challenges, such as water scarcity, limited arable land availability, and the need for sustainable and high-yield crop production. It offers opportunities for urban and peri-urban farming, making it a viable solution for increasing food security and promoting sustainable agriculture practices in the country.

Applications in India:

Hydroponic farming has diverse applications in India:

Urban Agriculture: Hydroponics is well-suited for urban areas, where space is limited, and fresh, locally grown produce is in high demand. Rooftop gardens, vertical farms, and container farming are popular choices for urban agriculture in India.

Commercial Greenhouses: Many commercial growers in India have adopted hydroponic systems for the production of various crops, including tomatoes, cucumbers, and leafy greens.

Research and Education: Hydroponic systems are used in research institutions and educational settings to study plant growth, nutrient management, and environmental control, contributing to agricultural innovation in the country.

Food Security: Hydroponic farming can help improve food security by providing a reliable source of fresh produce, even in regions with challenging climate conditions.

Types of Hydroponic Systems:

There are various hydroponic systems designed to cater to different crops and environmental conditions:

Drip System: Nutrient solution is delivered directly to the base of each plant via a network of tubes and pumps. Excess solution is collected and recirculated, minimizing waste.

Nutrient Film Technique (NFT): In NFT systems, a shallow film of nutrient solution flows over an inclined trough, with plant roots placed in the film. Roots draw nutrients and oxygen from this thin film.

Aeroponics: This system mists the plant roots with a nutrient-rich solution, providing both nutrients and oxygen to the roots through a fine mist. This method encourages rapid growth.

Deep Water Culture (DWC): Plants are suspended in oxygenated nutrient solutions in DWC systems. Air stones or diffusers are used to oxygenate the water, ensuring the roots receive an adequate oxygen supply.

Wick System: The simplest of all hydroponic systems, wick systems rely on capillary action to draw the nutrient solution from a reservoir into the growing medium. This is a passive system that requires no electricity.

Ebb and Flow (Flood and Drain): This system cyclically floods plant containers with the nutrient solution, then allows it to drain, providing oxygen to the roots. This mimics natural irrigation patterns.

Vertical Farming: Vertical hydroponic systems utilize vertical space, allowing for the stacking of plant layers. This approach maximizes crop production in limited space, making it suitable for urban environments.

Kindly visit the profile for more - https://krishilearning.com/

What you"ll discover here -

Educational Resources - Our blog serves as a treasure trove of educational content, including articles and lesson plans, all designed to enhance your understanding of agricultural principles, practices and new technology in agriculture. We explore cutting-edge technologies, such as hydroponics, aquaponics, precision farming, and more, to help you stay ahead in the ever-evolving world of agriculture.

We have designed our website to be user-friendly, making it easy for you to navigate, access, and engage with our content. We value your user experience.

Join Us in Cultivating Knowledge

Whether you are a farmer, a student, a teacher, or simply someone interested in the world of agriculture, krishilearning is here to guide you on your educational journey. Together, we can foster a more sustainable, innovative, and prosperous agricultural sector. Join us in cultivating knowledge, growing communities, and embracing the future of agriculture.

6 notes

·

View notes

Text

Get the Best in Agriculture: Reliable Rotavator Components from Ludhiana

Agriculture is the backbone of our economy, and ensuring its success starts with reliable equipment. When it comes to sourcing durable, efficient, and high-quality rotavator components, SBJ Nirmal Products in Ludhiana stands out as a trusted name in the industry. In this blog, we’ll delve into what makes SBJ Nirmal Products the go-to choice for farmers worldwide.

Introduction to SBJ Nirmal Products and Its Mission

At SBJ Nirmal Products, our mission is simple yet impactful: to empower farmers with top-notch agricultural components that enhance productivity and minimize equipment downtime. With decades of expertise in manufacturing rotavator parts, we’re committed to quality, innovation, and customer satisfaction.

Why Choose Ludhiana for Agricultural Components?

Ludhiana, often referred to as the "Manchester of India," is a hub for industrial excellence. Its well-established infrastructure, skilled workforce, and commitment to quality make it the perfect base for manufacturing agricultural components.

A Hub of Quality Manufacturing: Ludhiana's factories are renowned for precision engineering and consistent quality.

Global Reach from a Local Base: From Ludhiana, SBJ Nirmal Products serves customers not only in India but also in Bangladesh, Nepal, Sri Lanka, and beyond.

The Importance of Reliable Rotavator Components

Reliable components are crucial for maximizing efficiency in agriculture. Here’s why:

Enhancing Agricultural Productivity: Quality rotavator parts ensure smooth soil preparation, leading to better crop yields.

Reducing Equipment Downtime: Durable components reduce the frequency of repairs, saving time and money.

SBJ Nirmal Products: A Legacy of Excellence

With over 4,500 rotavator parts in our portfolio, SBJ Nirmal Products has built a legacy of trust and excellence.

Trusted by Farmers Worldwide: Our components are designed to meet the diverse needs of farmers across the globe.

Key Features of Our Rotavator Components

At SBJ Nirmal Products, every component is crafted with precision and attention to detail. Here are some standout features of our rotavator parts:

Durability and Longevity: Built to withstand tough agricultural conditions, our components last longer, offering unmatched value.

Precision Engineering: Our parts are manufactured to exact specifications, ensuring perfect compatibility with a wide range of rotavator models.

Cost-Effectiveness: We provide high-quality products at competitive prices, making advanced agricultural technology accessible to all.

A Deep Dive into Popular Rotavator Components

Our extensive range of rotavator parts includes some of the most sought-after components in the market:

Crown Pinions: Designed for optimal torque and smooth operation, these are essential for high-performance rotavators.

Stub Axles: Known for their robustness, our stub axles ensure stability and reliability during field operations.

Rotavator Blades: Crafted from high-grade materials, these blades deliver efficient soil cutting and mixing, enhancing field preparation.

SBJ Nirmal’s Commitment to Quality and Innovation

Quality and innovation are the cornerstones of our manufacturing process. Here’s how we ensure excellence:

ISO-Certified Manufacturing Processes: Our production facilities adhere to the highest international standards.

Use of Advanced Technologies: From CAD design to CNC machining, we leverage cutting-edge technology to deliver superior products.

Sustainable Practices in Component Manufacturing

We are dedicated to sustainable manufacturing practices that benefit both the environment and the community:

Eco-Friendly Materials: Our components are made using materials that are sustainable and recyclable.

Minimizing Waste and Maximizing Efficiency: Advanced manufacturing techniques help us reduce waste and optimize resource use.

Testimonials: Farmers Speak About SBJ Nirmal Products

Our commitment to quality and service has earned us glowing reviews from farmers worldwide:

Real-Life Stories of Success: Many farmers have shared how our rotavator parts have transformed their operations.

Positive Feedback from Around the Globe: From India to Nepal, our customers praise the durability and efficiency of our products.

How to Purchase from SBJ Nirmal Products

We make it easy for farmers and dealers to access our products:

Online Ordering Options: Our website offers a seamless ordering experience, complete with detailed product descriptions and specifications.

Dealer Networks in India and Beyond: Our extensive network ensures prompt delivery and reliable after-sales support.

Conclusion: Elevate Your Farming Efficiency with SBJ Nirmal Products

When it comes to reliable, high-quality rotavator components, SBJ Nirmal Products in Ludhiana is a name you can trust. With a legacy of excellence, a commitment to innovation, and a focus on sustainability, we are dedicated to empowering farmers worldwide. Choose SBJ Nirmal Products and experience the difference in agricultural efficiency and productivity.

#rotavator components#reliable agricultural parts#SBJ Nirmal Products#rotavator parts manufacturer#Ludhiana agricultural parts#high-quality rotavator components#durable rotavator parts#precision engineering in agriculture#cost-effective rotavator parts#crown pinions#stub axles#rotavator blades#sustainable manufacturing#ISO-certified rotavator parts#global rotavator parts supplier#rotavator parts in India#buy rotavator components online#agricultural productivity#farming efficiency#trusted rotavator parts

0 notes

Text

This Infographic highlights the essential components and versatile applications of "backhoe service". Backhoes are equipped with various features like excavator and loader buckets, booms, and hydraulic power, play crucial roles in agriculture, including land preparation, irrigation, livestock farming, and crop cultivation. Farmers benefit from their time efficiency, versatility, precision, cost-effectiveness. Let's dive into, for detailed study.

2 notes

·

View notes

Text

Steel Barns: What to Search for

Metal barns are reasonably current points that are typically considered progressively much better frameworks than the conventional ones constructed out of timber. Barns constructed from steel (steel) have a tendency to have several advantages over their wood cousins that are mainly engineering relevant, though some people find them much less eye-catching. In this write-up we discover such benefits as well as explain points to take note of if the visitor remains in the marketplace for a building of this classification, not only pertaining to the procedures included however also to the building contractors themselves.

The largest advantage steel barns have is that the material results in remarkable architectural design, enabling typically higher flexibility of layout. Steel has reasonably high tensile strength, helping with the building and construction of large open spaces if wanted in addition to high ceilings. From the mounting to the paneling to the roof covering, there is remarkable strength in all elements along with high precision in fitting those aspects with each other.

Another advantage is the longevity of the product as well as subsequently the buildings made from it. In many cases, the joints have to be seamed, but you'll locate that steel structures, if developed properly, withstand the scourges of weather condition such as high winds and snow. Of course, damage from wood-eating pests or from water is just not a concern with steel.

People have a tendency to connect barns with farming, as well as they usually have preconceived notions regarding their plus sizes and their purposes. However a great deal of adjustments have actually pertained to the industry. Barns come little, big, and also industrialized, and they are no longer conveniently pigeon-holed right into certain usages.

For instance, the modern version of these frameworks can still be made use of for storing livestock, however great deals of innovators have actually uncovered lots of other uses. Possibly an evident purpose is for RV storage. Yet nowadays metal barns are additionally constructed as houses, as workshops, or as workplace.

One thing we need to point out is that there is a distinction between the frameworks we have actually been talking about and also what are called pole barns. The only real distinction is that post barns do not have foundations yet are rather improved top of a grid of poles anchored to the ground. They often tend to be quick to build and also can be affordable, yet prospective clients need to comprehend what to anticipate in terms of compromises.

There are numerous fine service providers that construct metal barns and various other steel structures. Depending upon their target clients, their focus might get on the domestic market, on making fairly little, prefab, multi-purpose buildings, or on tackling bigger, also commercial tasks. Experience, the nature of in-house devices, and access to knowledgeable design are all consider determining what kind of professional would be right for your task.

Industrialized barns are barely distinguishable from modest-sized industrial buildings the framework for which is steel. Resistances are such that is can be cost-effective to pre-engineer all the beam of light components and also to develop the framing in the shop, followed by transferring the set up items to the building and construction site. In many cases, the steel house siding for a barn can be pre-fabricated in the shop.

If you want a structure with great deals of open space (for whatever reason), steel ought to be the selection of material since the layout is that a lot more attainable. Conceptually, this isn't that different from an aircraft hangar, as well as a great candidate for developing it is an industrial specialist with experience in the aviation market. Likewise, it is important to keep one's mind open in order not to be sidetracked by preconceived notions.

It is interesting to see just how the construction industry evolves as brand-new innovations pertain to market and also demand changes in new instructions. Do your homework to make sure you aren't caught off-guard. We have tried to show the reader what to seek in metal barns.

click here

youtube

2 notes

·

View notes

Text

Perfect Fit – How Customization Enhances Insulators and Bushings

In the rapidly advancing world of electrical systems, where efficiency and reliability are paramount, the need for customized solutions is growing. Insulators and bushings are critical components in electrical infrastructure, ensuring safety, performance, and longevity. Standard solutions may not always address unique requirements, and that is where customization plays a pivotal role.

In this blog, we delve into the importance of customization in insulators and bushings, exploring how tailored solutions from customized insulator and bushing manufacturers in India drive innovation and efficiency.

The Importance of Insulators and Bushings in Electrical Systems

Insulators and bushings play a crucial role in electrical equipment. They are designed to:

Prevent electrical leakage by separating conductors.

Enhance the safety and efficiency of power systems.

Withstand high voltages and harsh environmental conditions.

As electrical networks grow increasingly complex, there is a pressing need for customized components to meet specific challenges. This is where customized insulators and bushings come into the picture.

Why Opt for Customized Insulators and Bushings?

Customization allows manufacturers to design insulators and bushings tailored to precise requirements. Here are some key benefits:

1. Optimized Performance

Standard insulators and bushings may not fit all operational needs. Customized solutions ensure compatibility with unique designs, operational environments, and performance metrics. This is particularly critical in high-stress applications such as:

High-voltage power transmission.

Industrial power setups.

Specialized equipment like transformers and circuit breakers.

2. Enhanced Reliability

Custom designs consider factors such as voltage capacity, environmental conditions, and material requirements. For instance, epoxy pole housing offers superior durability and resistance, making it a preferred choice for demanding environments.

3. Material Versatility

Customization allows the selection of the most suitable materials. For example:

Epoxy insulator solutions are favored for their high mechanical strength, electrical insulation properties, and resistance to harsh conditions.

Epoxy bushing designs are ideal for providing electrical and mechanical support while withstanding environmental and operational stress.

4. Cost-Effectiveness

While customized solutions may have a higher upfront cost, they provide long-term savings by minimizing downtime, reducing maintenance costs, and enhancing system longevity.

Applications of Customized Insulators and Bushings

Customized insulators and bushings find applications across a wide range of sectors. Let us explore a few key areas:

1. Power Distribution Networks

Power networks rely heavily on reliable insulation and bushing systems. Custom solutions ensure components meet the specific demands of:

Voltage fluctuations.

Harsh weather conditions.

Compact designs in urban environments.

2. Electrical Transformers

Transformers are critical in power systems, and bushings play a vital role in their functionality. Customized epoxy bushing designs are engineered to enhance performance and ensure safe electrical conduction.

3. Circuit Protection Systems

Circuit protection devices like fuse cutouts require specialized housings. Fuse cutout housing can be customized to withstand electrical surges, ensuring the protection of connected equipment.

4. Renewable Energy Systems

The rise of renewable energy has introduced unique challenges for electrical components. Customized insulators and bushings are tailored to handle:

Higher voltage levels in solar and wind power systems.

Corrosive environments such as offshore wind farms.

How Customization Works

Customization is a collaborative process involving manufacturers and clients. Reputable customized insulator and bushing manufacturers in India follow a systematic approach:

1. Requirement Analysis

The first step is understanding the specific needs of the client. Factors like operational environment, voltage levels, and design constraints are carefully assessed.

2. Material Selection

Choosing the right material is crucial. For instance:

Epoxy pole housing is often selected for its excellent thermal stability and electrical insulation properties.

High-performance polymers or ceramics may be used for extreme environments.

3. Design and Prototyping

Manufacturers use advanced CAD software to design custom solutions. Prototypes are created to validate performance before mass production.

4. Testing and Quality Assurance

Customized components undergo rigorous testing to ensure they meet industry standards and client specifications. Testing includes:

Dielectric strength tests.

Mechanical stress tests.

Environmental resistance tests.

5. Production and Delivery

Once approved, the components are manufactured using advanced processes and delivered to the client.

Why Choose Indian Manufacturers for Customized Solutions?

India has emerged as a hub for high-quality electrical components. Here is why partnering with customized insulator and bushing manufacturers in India is a smart choice:

Expertise: Indian manufacturers have extensive experience in designing and producing customized solutions.

Cost-Effectiveness: Competitive pricing without compromising on quality.

Innovation: Use of advanced technologies and materials to meet global standards.

Sustainability: Commitment to eco-friendly manufacturing practices.

Radiant Enterprises: Your Partner for Customized Solutions

At Radiant Enterprises, we specialize in delivering high-quality customized insulators and bushings tailored to the unique needs of our clients. Our expertise extends to:

Epoxy insulator and bushing solutions that ensure top-notch performance and reliability.

Advanced epoxy pole housing designs for a variety of applications.

Durable fuse cutout housing options that protect your systems from electrical faults.

Our team works closely with clients to understand their requirements, ensuring every product meets their expectations. With a focus on quality, innovation, and customer satisfaction, we stand among the leading manufacturers in India.

Conclusion

The need for customized insulators and bushings in today’s electrical systems cannot be overstated. From enhancing performance and reliability to ensuring long-term cost-effectiveness, customization offers unparalleled advantages.

Partnering with a trusted customized insulator and bushing manufacturer in India, like Radiant Enterprises, ensures you receive components designed to meet your specific needs. With our expertise in epoxy insulators, epoxy bushings, fuse cutout housing, and more, we provide solutions that drive efficiency and reliability in your electrical systems.

Contact Radiant Enterprises today to learn how our customized solutions can transform your operations!

#Customised insulators and bushings#Customized insulator and bushing manufacturers in India#Epoxy pole housing#Fuse cutout housing

5 notes

·

View notes

Text

📰 TAEVision Engineering 's Posts - Wed, Jul 12, 2023 TAEVision 3D Mechanical Design • Parts AutoParts Aftermarket Precision Universal Joint MOOG Automotive Chassis Steering Suspension • Automotive Machinery Agriculture MercedesBenz GClass IRON Project 01 / 06 • Automotive Fashion NY NYC MercedesBenz SLS AMG 1️⃣ Data 096 Parts AutoParts Aftermarket Precision Universal Joint PrecisionUniversalJoint DriveTrain Components - FederalMogul ▸ TAEVision Engineering's Post on Tumblr 2️⃣ Data 103 Parts AutoParts Aftermarket MOOG Automotive Chassis ChassisParts Steering and Suspension Parts MAKE IT EASY. MAKE IT MOOG. FederalMogul ▸ TAEVision Engineering's Post on Tumblr 3️⃣ Data 282 Automotive Machinery Agriculture Farm Farms Farming MercedesBenz GClass GWagon OffRoad IRON Project 01 Shöckl Suffolk County NY ▸ TAEVision Engineering's Post on Tumblr 4️⃣ Data 264 Automotive Machinery Agriculture Farm Farms Farming MercedesBenz GClass GWagon OffRoad IRON Project 06 Shöckl Suffolk County NY ▸ TAEVision Engineering's Post on Tumblr 5️⃣ Data 358 3D Design Applications Automotive Fashion NY NYC Dreams in Manhattan NY NYC 'where dreams are made' MercedesBenz SLS AMG ▸ TAEVision Engineering's Post on Tumblr

📰 I just updated my Pressfolio: TAEVision Mechanics's Online Portfolio - Global Data - Jul 12, 2023 ▸ TAEVision Mechanics's Online Portfolio (last update)

Global Data - Jul 12, 2023

#TAEVision#engineering#3d#mechanicaldesign#parts#autoparts#aftermarket#Precision Universal Joint#PrecisionUniversalJoint#DriveTrain Components#FederalMogul#MOOG Automotive#chassis#steering#suspension#automotive#machinery#agriculture#MercedesBenz#GClass#GWagon#IRONProject#Suffolk County NY#fashion#NY NYC#Dreams in Manhattan#Manhattan#AMG#SLS#SLS AMG

1 note

·

View note

Text

Top Three Core Flat Cable Manufacturers You Should Know: Spotlight on Ambica Cables

In today's fast-paced industrial and infrastructure sectors, the need for reliable and high-quality wiring solutions is greater than ever. One such critical component is the three core flat cable manufacturers, widely used in submersible pumps, power systems, and control panels due to its flexibility, space-saving design, and durability.

When it comes to selecting the right manufacturer, not all cables are created equal. Here’s a look at some of the top three core flat cable manufacturers in India — with a special focus on Ambica Cables, a trusted name in the industry.

1. Ambica Cables: A Name Synonymous with Trust and Quality

Ambica Cables has earned a solid reputation as a leading manufacturer of high-performance three core flat cables. With decades of experience, the company combines precision engineering with robust quality control standards, ensuring reliable products that meet national and international benchmarks.

Key Features of Ambica's Three Core Flat Cables:

Made with high-grade electrolytic copper for superior conductivity

PVC insulation and sheathing for enhanced heat, moisture, and abrasion resistance

Ideal for submersible pumps and motors in agriculture and domestic use

Compliant with IS 694 and other relevant standards

What sets Ambica Cables apart is its customer-centric approach and commitment to consistent quality, making it a preferred choice for both large-scale infrastructure projects and small businesses alike.

Final Thoughts

Choosing the right cable manufacturer is crucial to the safety, performance, and longevity of your electrical systems. While there are many players in the market, Ambica Cables stands out for its deep industry expertise, reliable product range, and commitment to quality.

Whether you're installing a submersible pump in a farm or developing a large-scale commercial project, make sure your wiring solutions come from a name you can trust.

Explore more about Ambica Cables and discover why they are the go-to manufacturer for quality three core flat cables.

Visit:- https://www.ambicacables.com/three-core-flat-cables.html

0 notes